INTEGREX i-350H AG

Photo) INTEGREX i-450H S AG

Shown with optional equipment

The integration of INTEGREX multi-tasking with gear cutting and measurement

-

Process integration for high accuracy machining, reduction of in-process time and initial cost

-

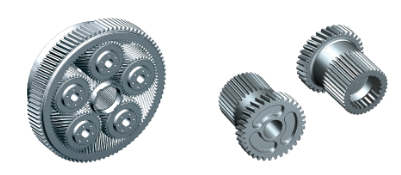

3 types of gear machining methods (gear skiving, hobbing and endmilling) can be performed for high-mix, small volume production to large production to meet your production requirements

-

Programs for cutting tool paths and measurement can be easily made in a short period of time

-

The INTEGREX AG SERIES deliver maximum versatility and provide more flexible production line

More details about the INTEGREX AG Series

Machine Specifications

| 1000 mm Bed (Universal) | Values | |

|---|---|---|

| CAPACITY | Chuck size main spindle | 10 " |

| Maximum machining diameter | 670 mm | |

| Bar work capability main spindle (dependent on chuck system) | 80 mm | |

| MAIN SPINDLE | Rotating speed maximum | 4,000 min-¹ |

| Motor output (40% ED rating) | 30.0 kW | |

| MILLING HEAD | Milling spindle speed maximum | 12,000 min-¹ |

| FEED AXES | Movement stroke X | 695 mm |

| Movement stroke Z | 1,077 mm | |

| Movement stroke Y | 300 mm | |

| Movement stroke B | 240° (-30° ~ +210°) | |

| AUTO TOOL CHANGER & MAGAZINE | Tool storage per magazine | 38 |

| 1500 mm Bed (Universal) | Values | |

|---|---|---|

| CAPACITY | Chuck size main spindle | 10 " |

| Maximum machining diameter | 670 mm | |

| Bar work capability main spindle (dependent on chuck system) | 80 mm | |

| MAIN SPINDLE | Rotating speed maximum | 4,000 min-¹ |

| Motor output (40% ED rating) | 30.0 kW | |

| MILLING HEAD | Milling spindle speed maximum | 12,000 min-¹ |

| FEED AXES | Movement stroke X | 695 mm |

| Movement stroke Z | 1,585 mm | |

| Movement stroke Y | 300 mm | |

| Movement stroke B | 240° (-30° ~ +210°) | |

| AUTO TOOL CHANGER & MAGAZINE | Tool storage per magazine | 38 |